| Bump Steer is when your wheels steer themselves without input from the steering wheel. The undesirable steering is caused by bumps in the track interacting with improper length or angle of your suspension and steering linkages. |

| Most car builders design their cars so that the effects of bump steer are minimal. However, you must still take care to bolt on your suspension carefully so as not to create unwanted bump steer. Make sure that you are always using the correct components for a particular car. Bump steer must be designed into the car and cannot be adjusted out if improper parts are used or if pivot points are moved without considering bump steer design principles. |

| In order to accomplish zero bump the tie rod must fall between an imaginary line that runs from the upper ball joint through the lower ball joint and an imaginary line that runs through the upper a-arm pivot and the lower control arm pivot. In addition, the centerline of the tie rod must intersect with the instant center created by the upper a-arm and the lower control arm (See diagram below). |

| The instant center is an imaginary point that is created by drawing a line from the upper a-arm ball joint through the a-arm pivot where it is intersected by an imaginary line that extends from the lower ball joint through the inner control arm pivot. Where the two imaginary lines intersect is the instant center. |

| Sounds complicated? Really it is very simple. To achieve zero bump the front end must be designed correctly. The tie rod must travel on the same arc as the suspension when the car goes through travel. Simply matching lengths and arcs to prevent any unwanted steering of the front tires. |

| To exaggerate, if the tie rod were only 10″ long and the suspension were 20″ long then when the suspension traveled the tie rod angle would shorten much quicker than the suspension arc. In this scenario the tie rod would shorten much quicker through travel than the suspension and the car would toe in drastically over bumps. The shorter arc of the tie rod would pull on the spindle and toe it in through travel. |

Proper Tire Care

Tire Pressure and Temperature

Using the proper tools to arrive at the correct tire pressure is critical to making your race car perform at the optimum level.

Air is about 78% nitrogen and it is free. But air also contains about 21% oxygen and water vapor. Filling a tire with 100% nitrogen has some important advantages over filling with air.

One is that nitrogen molecules are larger than oxygen molecules, so tires leak less gas over time. Another benefit is that pure nitrogen doesn’t heat up as fast, so tire pressure gain is significantly less!

Another commonly overlooked factor that affects tire pressure is the temperature of the tire when the pressure is set before hitting the track. Since air or nitrogen is a gas, it expands when heated and contracts when cooled.

The rule of thumb is that for every 10 degree Fahrenheit change in air temperature, your tire’s inflation pressure will change by about .8 psi (up for higher temperatures and down for lower).

For example purposes, let’s assume that your two rear tires are sitting in direct sunlight with an ambient temperature of 85 degrees. The two front tires are left inside the trailer where the temperature is only 65 degrees. Prior to hitting the track for practice, all four tires are inflated to 30 psi. When the two front tires are heated to 85 degrees (same temperature as the back tires) the actual pressure in these two tires will have increased to almost 32 psi!

Race Ready Scaling

Scaling A Race Car Properly

Race Ready

In order to scale your car properly it must be ready to go. For the most accurate results the car must be fully prepared. If it is not “race ready” then any changes that you make will have an effect on your final setup and what you have put in your notes. So, what do you need to have done to be “race ready”?

- Fuel full

- Radiator full

- Oil tank full and motor ran or too much oil can be in the pan

- Gear oil full

- Transmission full

- Power steering full

- Lead bolted in

- Stagger set

- Tire pressure set

- Camber set

- Rear end square

When Scaling your car, these are critical for accurate scaling. If these are not done properly, scaling will be altered greatly when raced

Fuel and Line Maintenance

Now is a good time to get that carburetor rebuilt. If you do it yourself, make sure to clean the jets and all passages. Check to be sure the throttle shaft is moving freely and is free from any restrictions that might make it stick. A sticky throttle shaft is hard to detect when the carburetor is on the car with the throttle springs attached.

Remove, clean, and inspect the fuel tank and bladder once a year. This item, too, has a life and a manufacturer’s date stamped on the fuel cell. Most sanctioning bodies require using a fuel cell that is less than five years old from the date of manufacture. Check your rules.

The fuel filter should be replaced often. This is not a budget breaker and is good insurance in making sure adequate fuel is supplied to the engine.

Fuel lines, fuel tank, and fuel filters – Fuel lines can get hard and brittle over time. Rubber has a limited life span, and we should never push our luck on keeping our fuel lines around too long. If the budget allows, replace them every year. If you ever have problems with foreign matter entering the fuel tank, be sure to replace the fuel lines once the fuel tank has been cleaned out.

Maintain Rearend Effectivness

Rear end maintenance – The rear end must be maintained properly and, in many cases, often. Rear lube temperatures can be very high. This reduces the effectiveness of the lubricant and can help shorten the life of some of the internal components.

In a Detroit Locker-type rear end, the springs are the life of the system. High heat can weaken these springs, and if the rate decreases over time, the rear end will not lock up properly and only one wheel will end up driving the car off the turns. The handling goes away once this happens, and the crew often searches for a setup fix to no avail. If running this type of rear end, rate and/or replace these springs often. To neglect this critical area is to tempt fate. Many racers have lost out to differential springs that have gone bad.

For traction sensing types of rear ends, the many gears that work to sense torque in order for the system to function properly must be in good shape or the car will not handle properly and will be inconsistent off the corners. Often, replacement must be done for these small gears every three or four races, depending on the extent of heat and abuse. Contact the manufacturer for detailed information on proper maintenance.

Rear end lubricant coolers and circulatory systems can greatly increase the life of any rear end by keeping the temperatures down to levels that will not weaken the locker springs, reduce the effectiveness of the lubricant, or, in some cases, literally melt the aluminum gears.

Brake Rotor Wear

Rotor failure – The brake rotors are a source of failure that can cause damaging effects such as a locked-up wheel. This can, in turn, lead to loss of control and a high-speed impact with the wall or other cars. When cracks appear in the face of the rotor, it is time to replace them. It is common for rotors to exhibit hairline surface cracks across the entire surface of the rotor. But if the cracks are too deep in appearance, they can lead to pieces of the rotor breaking off with obvious negative results.

4-link suspension information

4 LINK DIRT SUSPENSION

TIGHTEN CAR ON CORNER ENTRY

• Raise left side frame mounted panhard bar on chassis

• Lower panhard bar on pinion mount

• Stiffen left front spring

• Raise left side ride heights (rock up)

• Soften 6th coil spring

LOOSEN CAR ON CORNER ENTRY

• Raise panhard bar on pinion mount

• Soften left front spring

• Stiffen left rear spring

• Increase left side percentage

• Lower left side ride heights

• Stiffen 6th coil spring

• Increase left rear bite

TIGHTEN CAR ON CORNER EXIT

• Increase left rear bite

• Move 5th coil or torque link left

• Stiffen left rear spring

• Soften right rear spring

• Stiffen right front spring (may affect

ability to steer in middle and entry).

LOOSEN CAR ON CORNER EXIT

• Decrease left rear bite

• Soften left rear spring

• Lower left side ride heights

• Move 5th coil or torque link right

TO MAKE CAR STEER MORE

POSITIVE ON CORNER ENTRY

AND THROTTLE

• Soften right front spring

TO TIGHTEN CAR OVERALL

• Raise center of gravity height (raise ballast, left side ride

heights)

• Stiffen left side springs

• Decrease right rear trail (shorten right side 4 link rods

2 turns at a time)

• Reduce stagger

TO LOOSEN CAR OVERALL

• Increase stagger

• Increase right rear trail (lengthen right side 4 link rods

2 turns at a time)

• Lower center of gravity height (lower ballast, left side ride

heights)

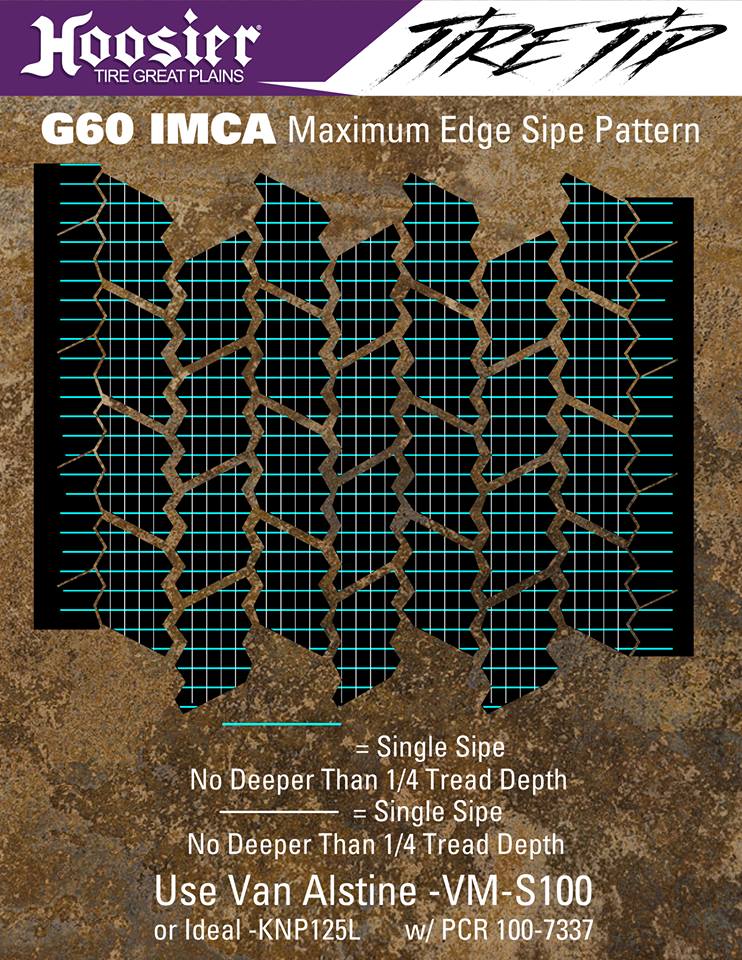

Tire Siping patterns for G 60’s

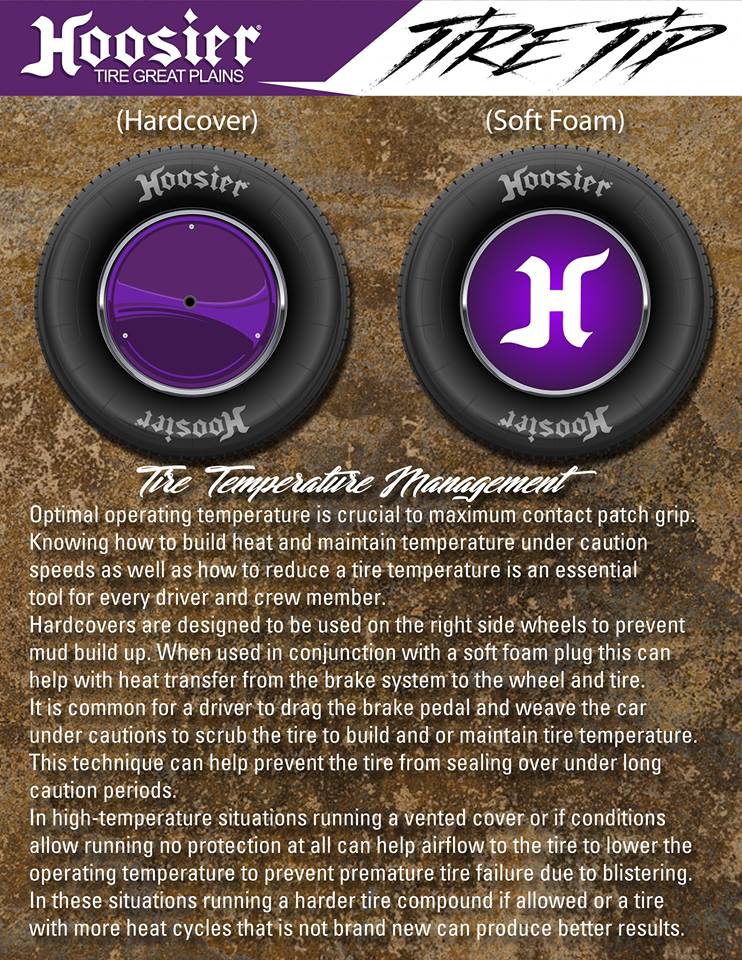

Tire Temps/ Cover or Foam

Look at picture

Wheel Offset Changes

Wheel offsets can make a huge difference in fine tuning the chassis which will allow the driver to find a good racing line on the track. “If your car is really tight or really loose during hot laps, you have to take a look at the things that are going to make the biggest difference. Wheel offsets are very important. You can change a wheel on the car without disturbing the scaling that you’ve done at the garage.

“ illustrated the point by telling us what he has seen at various tracks over the years, “Too many times we see guys go out on the track for hot laps when the track is muddy, come off the track and dial in 10 rounds on the weight jack. Then they go out and run a heat race when the track is tacky. When they come off they take the 10 rounds back out and dial in 10 rounds somewhere else. By feature race time, these guys have no clue where the weight and balance of the car is.”

The changes that you can make using wheel offsets, “If you find yourself with an extremely tight car during hot laps, you can run less offset in the right front or you can move the left front or right rear out.” Merritt explained that it helps to have a set of eyes watch the car on the track to verify what the driver is feeling. “Your spotter can watch the driver’s hands on the corner entry and it will pretty much tell him everything.”

Continued by saying, “If the problem is tight on entry, you can move the right front in to help the car pivot better. If the track is a flatter track with minimal banking, I like to move the left front out which will also help the car turn better.” If your car is wicked loose, Merritt says you do the reverse. “If you are making changes with tire stagger and wheel offsets, you’re never messing with the true balance of the racecar. “Key to success is making any changes for the track conditions you expect to see at the later stages of the feature race.